Table of Contents

Atomization technology is revolutionizing various industries by providing innovative solutions for processes that require the transformation of liquids into fine particles or droplets. From pharmaceuticals to agriculture, Atomization technology is enhancing efficiency, improving product quality, and enabling new applications. This article explores the history, principles, applications, and future prospects of atomization technology, emphasizing its transformative impact across multiple sectors.

Understanding Atomization Technology

Atomization technology refers to the process of breaking up a liquid into fine droplets or particles, typically using high-pressure nozzles, ultrasonic waves, or other mechanical means. This technology is critical in applications where precise control over droplet size and distribution is essential. Atomization technology has evolved significantly over the years, driven by advances in engineering and material science, and it continues to be a key component in many modern industrial processes.

History of Atomization Technology

The origins of atomization technology can be traced back to ancient times when early civilizations used rudimentary techniques to disperse liquids for various purposes. However, significant advancements in atomization technology began in the late 19th and early 20th centuries with the development of high-pressure nozzles and spray systems. The invention of the aerosol spray can in the 1920s marked a major milestone, paving the way for the widespread use of atomization in consumer products.

In the latter half of the 20th century, advancements in fluid dynamics and material science led to the development of more sophisticated atomization technologies, including ultrasonic and electrostatic atomizers. These innovations enabled greater precision and control over the atomization process, opening up new possibilities for industrial and scientific applications.

Principles of Atomization Technology

Atomization technology relies on several key principles to achieve the desired droplet size and distribution. The most common methods of atomization include:

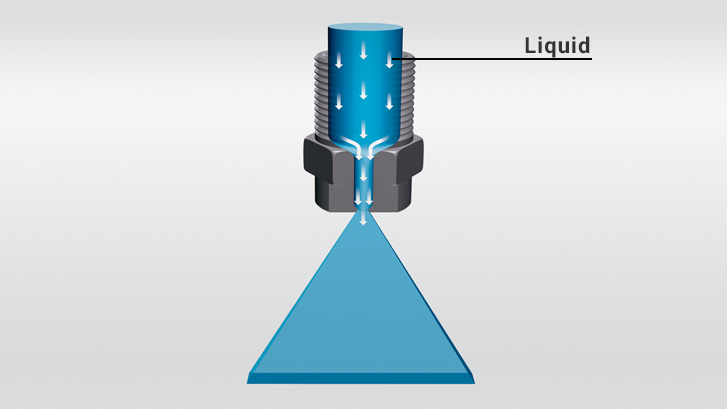

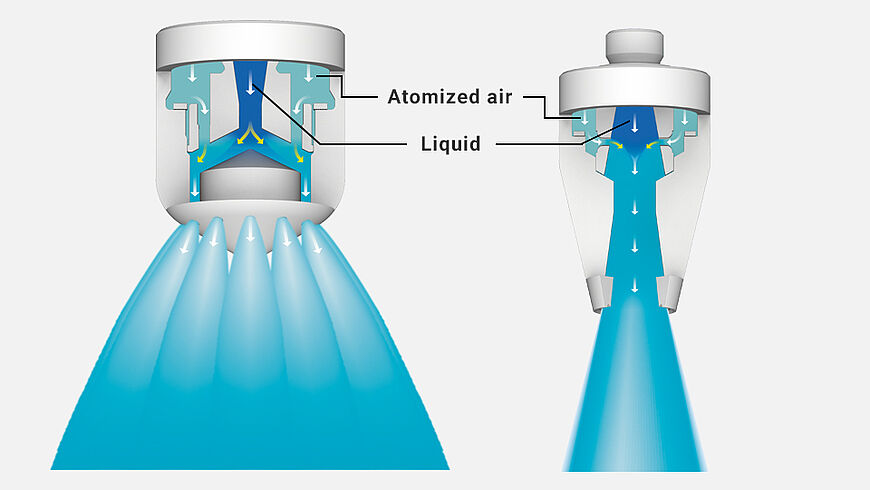

High-Pressure Atomization

High-pressure atomization involves forcing a liquid through a small nozzle at high pressure, causing it to break up into fine droplets. This method is widely used in applications such as fuel injection, spray painting, and agricultural spraying. The droplet size and distribution can be controlled by adjusting the pressure, nozzle size, and fluid properties.

Ultrasonic Atomization

Ultrasonic atomization uses high-frequency sound waves to create vibrations in a liquid, causing it to form fine droplets. This method is particularly useful for applications that require precise control over droplet size and minimal disruption of the liquid’s properties. Ultrasonic atomization is commonly used in medical nebulizers, humidifiers, and certain industrial processes.

Electrostatic Atomization

Electrostatic atomization involves applying an electric charge to a liquid, causing it to disperse into fine droplets due to electrostatic forces. This method is highly efficient and can produce very uniform droplet sizes. Electrostatic atomization is used in applications such as electrostatic spray painting, crop spraying, and in some advanced manufacturing processes.

Applications of Atomization Technology

Atomization technology has a wide range of applications across various industries, each benefiting from the ability to precisely control the dispersion of liquids. Key applications include:

Pharmaceutical Industry

In the pharmaceutical industry, Atomization technology is crucial for the production of inhalable drugs, vaccines, and other aerosolized medications. Ultrasonic and high-pressure atomizers are used to create fine droplets that can be easily inhaled or absorbed by the body. This technology ensures precise dosage and improves the efficacy of drug delivery.

Agriculture

Atomization technology plays a vital role in agriculture, particularly in the application of pesticides, herbicides, and fertilizers. High-pressure and electrostatic atomizers enable the efficient and uniform distribution of these substances, reducing waste and ensuring better coverage. This leads to improved crop yields and reduced environmental impact.

Food and Beverage Industry

In the food and beverage industry, atomization technology is used for applications such as spray drying, flavoring, and coating. Spray drying, for example, involves atomizing a liquid food product into fine droplets that are then dried to form a powder. This process is used to produce powdered milk, coffee, and various flavorings. Atomization technology ensures consistent product quality and enhances the efficiency of production processes.

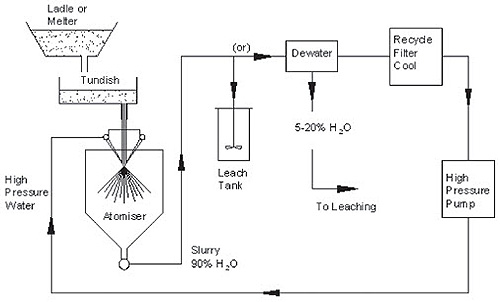

Manufacturing

Atomization technology is integral to various manufacturing processes, including spray painting, metal coating, and additive manufacturing. Electrostatic and high-pressure atomizers are used to apply coatings and paints uniformly, improving product quality and reducing material waste. In additive manufacturing, atomization technology is used to create fine metal powders that are essential for 3D printing processes.

Environmental Control

Atomization technology is also used in environmental control applications, such as air humidification, dust suppression, and odor control. Ultrasonic atomizers are commonly used in humidifiers to maintain optimal humidity levels in indoor environments. High-pressure atomizers are used to suppress dust in mining and construction sites, improving air quality and worker safety.

Personal Care Products

In the personal care industry, atomization technology is used to create fine mists for products such as perfumes, deodorants, and hair sprays. The precise control over droplet size ensures a consistent and pleasant user experience. Atomization technology also enables the development of innovative products, such as aerosol-based skincare treatments and disinfectants.

Future Prospects of Atomization Technology

The future of atomization technology looks promising, with ongoing advancements and emerging applications driving its evolution. Key trends and developments include:

Advanced Materials and Nanotechnology

Advancements in materials science and nanotechnology are opening up new possibilities for atomization technology. Researchers are developing advanced materials that can enhance the efficiency and precision of atomizers. Nanotechnology is also being integrated into atomization processes to create ultra-fine droplets for specialized applications, such as targeted drug delivery and advanced coatings.

Smart and Connected Atomizers

The integration of smart technology and the Internet of Things (IoT) is transforming atomization technology. Smart atomizers equipped with sensors and connectivity features can monitor and adjust parameters in real-time, optimizing performance and efficiency. This is particularly beneficial in industrial applications, where precise control and monitoring are critical.

Environmental Sustainability

Environmental sustainability is a growing focus in the development of atomization technology. Researchers are working on eco-friendly atomization processes that minimize waste and reduce energy consumption. For example, innovations in electrostatic spraying techniques aim to improve efficiency and reduce the environmental impact.

Healthcare Innovations

In the healthcare sector, atomization technology is poised to play a significant role in the development of new treatments and therapies. Researchers are exploring the use of atomizers for the precise delivery of gene therapies, vaccines, and biologics. The ability to create ultra-fine droplets ensures better absorption and efficacy, opening up new possibilities for medical treatments.

Enhanced Consumer Products

The consumer market for Atomization technology continues to grow, with new and enhanced products being developed for personal care, home, and recreational use. Innovations in atomization technology are enabling the creation of more effective and user-friendly products, such as smart air purifiers, advanced skincare mists, and portable disinfectant sprayers.

Conclusion

Atomization technology is transforming a wide range of industries by providing innovative solutions for the precise dispersion of liquids. From pharmaceuticals and agriculture to manufacturing and personal care, atomization technology enhances efficiency, improves product quality, and enables new applications. The continuous advancements in this field, driven by materials science, nanotechnology, and smart technology, promise to further revolutionize the way liquids are atomized and used.

Atech Flash Technology, as a leader in the atomization technology industry, is at the forefront of these innovations. Their commitment to quality, reliability, and customer satisfaction ensures that they continue to provide cutting-edge solutions that meet the evolving needs of their customers. As atomization technology continues to advance, Atech Flash Technology is poised to play a significant role in shaping the future of this dynamic field, driving progress and innovation across multiple sectors.

For More Information Please Visit These Websites Mindmeister And arturia