Table of Contents

Introduction:

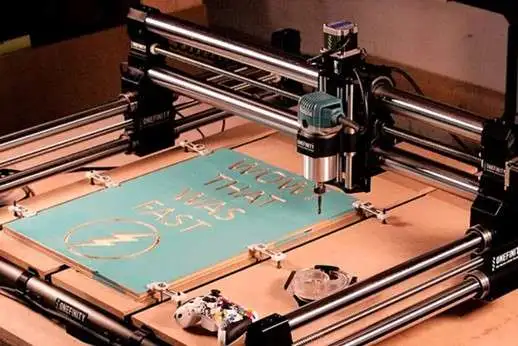

CNC (Computer Numerical Control) routers have revolutionized the world of woodworking, fabrication, and prototyping, offering unparalleled precision, efficiency, and versatility in material processing. From intricate carvings and precise joinery to custom signage and intricate moldings, CNC routers empower craftsmen, artists, and manufacturers to bring their creative visions to life with remarkable accuracy and consistency. In this comprehensive guide, we will explore the world of CNC routers, delving into their technology, applications, benefits, and the ways in which they have transformed the manufacturing and woodworking industries.

Understanding CNC Routers:

A CNC router is a computer-controlled cutting machine that utilizes a rotating cutting tool to remove material from a workpiece, typically wood, plastic, foam, or composite materials. Unlike traditional handheld routers or manual milling machines, CNC routers are programmable and automated, allowing for precise control over cutting paths, depths, and speeds. The CNC router receives instructions from a computer-aided design (CAD) file, which dictates the desired geometry and toolpaths for the cutting operation.

Key Components of a CNC Router:

Machine Bed:

The machine bed is the flat surface on which the workpiece is placed and secured during the cutting operation.

It provides a stable platform for the CNC router gantry and ensures accuracy and repeatability in cutting.

Gantry:

The gantry is the bridge-like structure that moves along the X and Y axes, carrying the cutting tool.

It is typically supported by precision linear guides or rails to ensure smooth and accurate movement.

Spindle:

The spindle is the motorized cutting tool holder that rotates at high speeds to remove material from the workpiece.

CNC routers may use different types of spindles, including router motors, spindle motors, or high-frequency spindles, depending on the application and material being cut.

Cutting Tool:

The cutting tool is the router bit or end mill that performs the cutting operation.

CNC routers can accommodate a wide range of cutting tools, including straight bits, ball nose bits, V-bits, and specialty profiles, to achieve various cutting effects and surface finishes.

Controller:

The controller is the brain of the CNC router system, responsible for interpreting the CAD file instructions and translating them into precise movements and cutting commands.

It may consist of a dedicated CNC controller, computer interface, and software for programming and operating the CNC router.

Applications of CNC Routers:

CNC routers find applications in a wide range of industries and disciplines, offering versatile capabilities for material processing, fabrication, and prototyping. Some common applications of CNC routers include:

Woodworking:

CNC routers are widely used in woodworking for cutting, carving, engraving, and shaping wood components.

They are employed in furniture making, cabinetry, architectural millwork, and decorative woodworking projects to achieve intricate designs and precise joinery.

Sign Making:

CNC routers are ideal for producing custom signs, logos, and lettering from various materials, including wood, plastic, acrylic, and aluminum.

They enable sign makers to create intricate designs, 3D carvings, and dimensional lettering with high precision and repeatability.

Prototyping and Model Making:

CNC routers are valuable tools for rapid prototyping and model making in product design and development.

They can quickly and accurately fabricate prototypes, scale models, and mock-ups from a variety of materials, allowing designers to test and iterate their ideas before production.

Foam Cutting and Packaging:

CNC routers are used in the packaging industry for cutting foam inserts, protective packaging, and custom packaging solutions.

They enable manufacturers to create precise and custom-fit packaging solutions that provide optimal protection for fragile or sensitive products during shipping and handling.

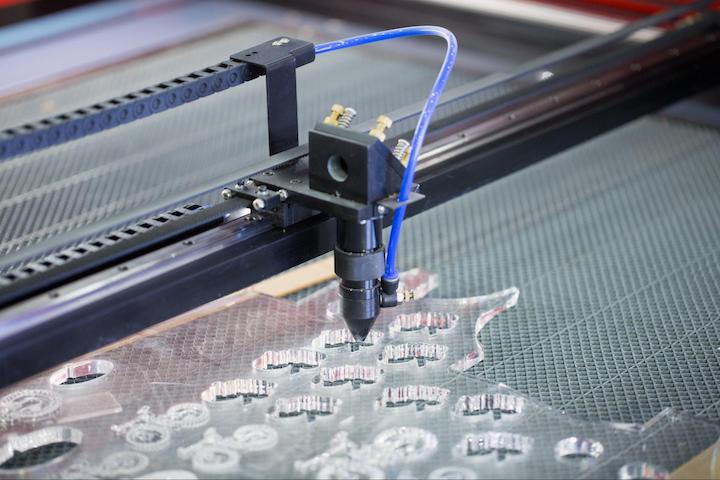

Metal Fabrication:

While primarily used for cutting wood and plastics, CNC routers can also be adapted for metal fabrication applications.

With the appropriate cutting tools and machining parameters, CNC routers can cut and engrave aluminum, brass, copper, and other non-ferrous metals with precision and efficiency.

Benefits of CNC Routers:

CNC routers offer numerous benefits over traditional manual machining methods, including:

Precision and Accuracy:

CNC routers provide unparalleled precision and accuracy in cutting, carving, and shaping operations, ensuring consistent results from part to part.

Efficiency and Productivity:

CNC routers automate the cutting process, reducing manual labor and increasing production throughput.

They can run continuously for extended periods, maximizing efficiency and productivity in manufacturing environments.

Versatility and Flexibility:

CNC routers are highly versatile machines that can accommodate a wide range of materials, cutting tools, and cutting geometries.

They offer flexibility in design and fabrication, allowing users to create complex shapes, contours, and textures with ease.

Reproducibility and Consistency:

CNC routers enable precise replication of designs and patterns, ensuring consistency and uniformity in manufactured parts and products.

This reproducibility is particularly valuable in mass production and assembly line manufacturing settings.

Design Freedom and Complexity:

CNC routers offer virtually unlimited design possibilities, allowing users to create intricate and complex shapes that would be difficult or impossible to achieve with traditional machining methods.

This design freedom opens up new opportunities for innovation and creativity in product design and fabrication.

Conclusion:

CNC routers are powerful tools that have transformed the manufacturing and woodworking industries, offering unmatched precision, efficiency, and versatility in material processing. From woodworking and sign making to prototyping and metal fabrication, CNC routers empower craftsmen, designers, and manufacturers to bring their creative visions to life with extraordinary accuracy and consistency. By understanding the technology, applications, and benefits of CNC routers, users can unlock the full potential of these innovative machines and take their projects to new heights of precision and craftsmanship.

For More Information Please Visit These Websites Mindmeister And Arturia